Bolt tightening inspection of key parts of the wheel loader

During operation, if the bolts in key parts are loosened, we can obviously feel the whole vehicle shaking or making abnormal noises. Long-term neglect may cause safety accidents and property damage. After the new car has been run in for 100 hours, we must carry out the inspection of key parts of the bolts. Torque check and recheck torque every 500 hours thereafter.

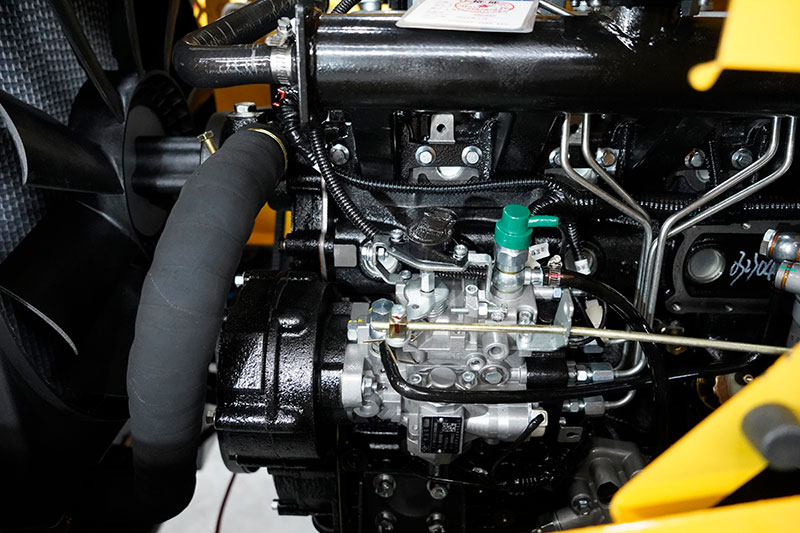

The key parts to be inspected include engine, gearbox, cab assembly support, front and rear axles and frame connections, rims, drive shafts, front and rear frame hinges, working devices, etc.

For the tightening of the connecting bolts, you can check whether the bolts are loose by hand-triggering and observing whether there is any displacement of the tightening mark line. According to the specifications of the tightening bolts, select the correct torque for tightening.